Quick Details

Description

PEAK-350 lead-free dual wave soldering machine

Include:

1)Buffer conveyor

Linkage PCB loading mode with stainless steel chain

2)Conveyor system

The conveyor system is equipped with new-type titanium double hook finger and aluminium alloy rail prevents rail from distorting; Manual PCB width adjustment with digital figure display; conveying angle adjustable, equipped with angle meter of digital display; conveying speed adopts inverter control of stepless adjustment.

3)Spray fluxer system

The spray fluxer system employs modular type design, spray movement adopts step motor control; automatic adjustment in accordance with PCB spraying length, width and speed, using micro adjustment unit of pressure meter to adjust spray flux and the measure of spray grain; isobarically unit supplying flux, flux level alarm and automatic flux supply; air exhaust and filter system of strong power.

4)Preheating system

Drawer type modular design, heating type of infrared heating tube +micro hot--air circulation, three subsection temperature zones(two of infrared heating tube+one of hot air), the length of preheating zone:1.8m, PID temperature controlling method.

5)Solder pot system

Apply tailor-made cast iron material to solder pot inner body, surface processing giving better prevention from oxidation. Linkage motor driving wave, speed adjusted by inverter, solder dross flow and oxide reducing equipment, manual and automatic methods for controlling pot in/out, digital display height, outer heating unit, PID temperature control method and lower-liquid-level alarm.

6)Cooling system

Upper and lower forcible air cooling system

7)Finger cleaning unit

Special hair brush for cleaning.

8)Control system

Industrial PC+PLC system for wiring control, Windows operation interface with Chinese/English version, functions of temperature profile test and data storage etc.

9)Others

--PCB size: 50~350mm(W)*120mm(H)

--Component height:750±20mm

--Conveying speed: 500~1800mm/Min.

--Conveying angle: 4~7º

--Conveying direction: from left to right

--Fluxer capacity: Approx.18L

--Fluxer flow volume: 0~250ml/min.

--Spraying air exhaust: Approx.30m3/min.

--Compressed air: 4~6Bar. 100L/min.

--Preheating temperature: Max.200℃

--Temperature of solder pot: Max.300℃

--Capacity of solder pot: Approx.500Kg

--Height of wave: Approx.12mm

--Dimension: 3600(L)*1400(W)*1700(H)mm

--Net weight: Approx.1500Kg

--Power supply: three phase 380V 50Hz

--Power consumption: Approx.36KW

--Running power: Approx.11KW

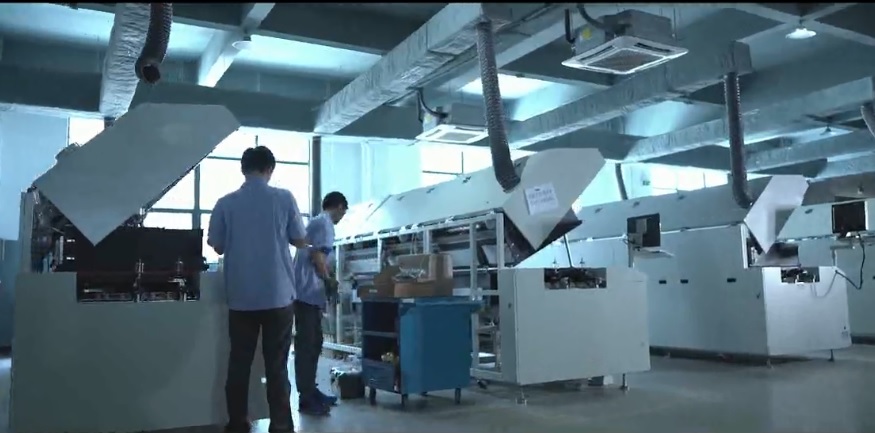

Company Introduction

Unisplendour Suneast Technology (Shenzhen) Co., Ltd.( Abb r: Unisplendour Suneast Technology ) is the core enterprise of Unisplendour Technology (holdings), which was founded in Hong Kong in 1984 and built its industrial area in Shenzhen in 1999.

Equip with the modernized industrial park and advanced R&D facilities, Unisplendour Suneast Technology owns strong system integrated ability in R&D, design, production, processing, automatic and manufacturing equipment, its sales network is all over the world. It achieves technical and strategic cooperation with Tsinghua University, Chinese University of Hong Kong, Hong Kong University of Science & Technology, Harbin Institute of Technology and becomes the first-class technology at home and abroad.

Unisplendour Suneast Technology always devotes itself to providing the complete solution with intelligent equipment, MES and LOA data series information-based platform. Years by years,Unisplendour Suneast Technology keeps improving and diversified develops,integrates all sources in the upstream and downstream, improves the electronic production technology industry chain, and widely service in the field of auto electronics, electron machinery, household appliances, medical, military, railway transportation, communications, logistics, finance and other different areas. With the unceasing growth, Unisplendour Suneast Technology gradually actualizes brand strategy,aims at “Intelligent Manufacturing, Smart Future”, devotes itself to researching, developing, producing and selling high-end equipment, and especially occupies a pivotal position in the SMT surface mount device at home and abroad.

Unisplendour Suneast Technology always provides with nanny service, consultative selling for customers. At the same time, as a subsidiary of Unisgroup,,Unisplendour Suneast Technology will strengthen the strategic target of the group, and create itself to be world-class high-tech enterprises.