Biomass Material Drying Process

The best moisture content to pelletizing is about 11-17%. So before pelletizing, a drying machine is needed to make the moisture content reaches the required standards. You should choose the most suitable drying machine from rotary dryer and pipe dryer according to the wood powder moisture and handling capacity.

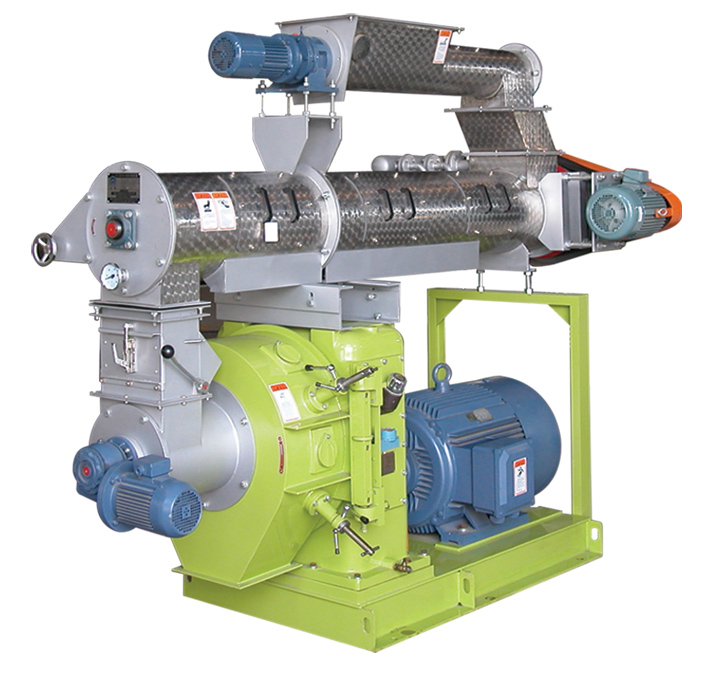

Wood Pelletizing Process

Pellet mill is the significant part of the wood pellet production line, and has reliable and stable performance. It is specially designed for compacting of wood, straw, and other biomass sources into pellets. Capacity ranges from 1T to 10T per hour. You can choose ring die pellet mill or flat die pellet mill depend on your capacity requirements. Our MZLH series Ring die pellet mill is best choice for large scale production, while AMSPLM series flat die pellet mill is suitable for small pellet production line. The final wood pellets will have high density and high heating value. Any doubt please feel free to contact with us for detailed information.

Wood Pellet Cooling Process

After pelletizing process, the temperature of wood pellets is between 60-80 degrees and the moisture content is close to 15%. So a cooler must be used to reduce their surface temperature and the moisture content which makes the wood pellets easy to store, meanwhile helps screen good and pure pellets.

Wood Pellet Packing Process

After the cooling process, packing process is necessary to protect the wood pellets from the damp. Amisy automatic wood pellet weighing & packing system adopts PLC control with high weighing accuracy and easy operation is your best choice.

Why Choose Amisy Wood Pellet Line?

* Stable and Durable Equipment Function.

* Competitive Price with Good Quality.

* Lower Energy Consumption and Less Manpower.

* Customized Capacity to Meet Different Clients’ Requirements* 12 Years experience and Professional Technical Guidance

* 2 Years Guarantee, Reliable After-sale Service Team.