Quick Details

Parameter

Model : JL-90 (90mm wide frame)

Thickness : 0.5 5- 1.5mm

Accuracy : +/- 1mm

Power : 5.5KW

Description

Automatic C/U Shape Light Steel Keel Roll Forming Machine

If you are interested in my product, contact me at any time! I am waiting for you~

wangy@mec.com.cn

Whats app: 0086-15164015358

zhaoyh@mec.com.cn

Whats app: 0086-18842637815

Model

JL-75 (75mm wide frame) ;

JL-90 (90mm wide frame) ;

JL-140 (140mm wide frame) ;

Thickness

0.5 5- 1.5mm;

Yield Strength Q235 Q345 LQ550 ;

High Precision

Adjustment Error: +/- 1mm ;

Production Error: +/- 1mm ;

Light Weight and Small Size

Roll Forming Machine Dimension: 3000*500*1305mm Weight: 740KG ;

Rewinding Machine Demension: 1160*950*250mm Weight: 183KG ;

Production Line Length: 7000mm ;

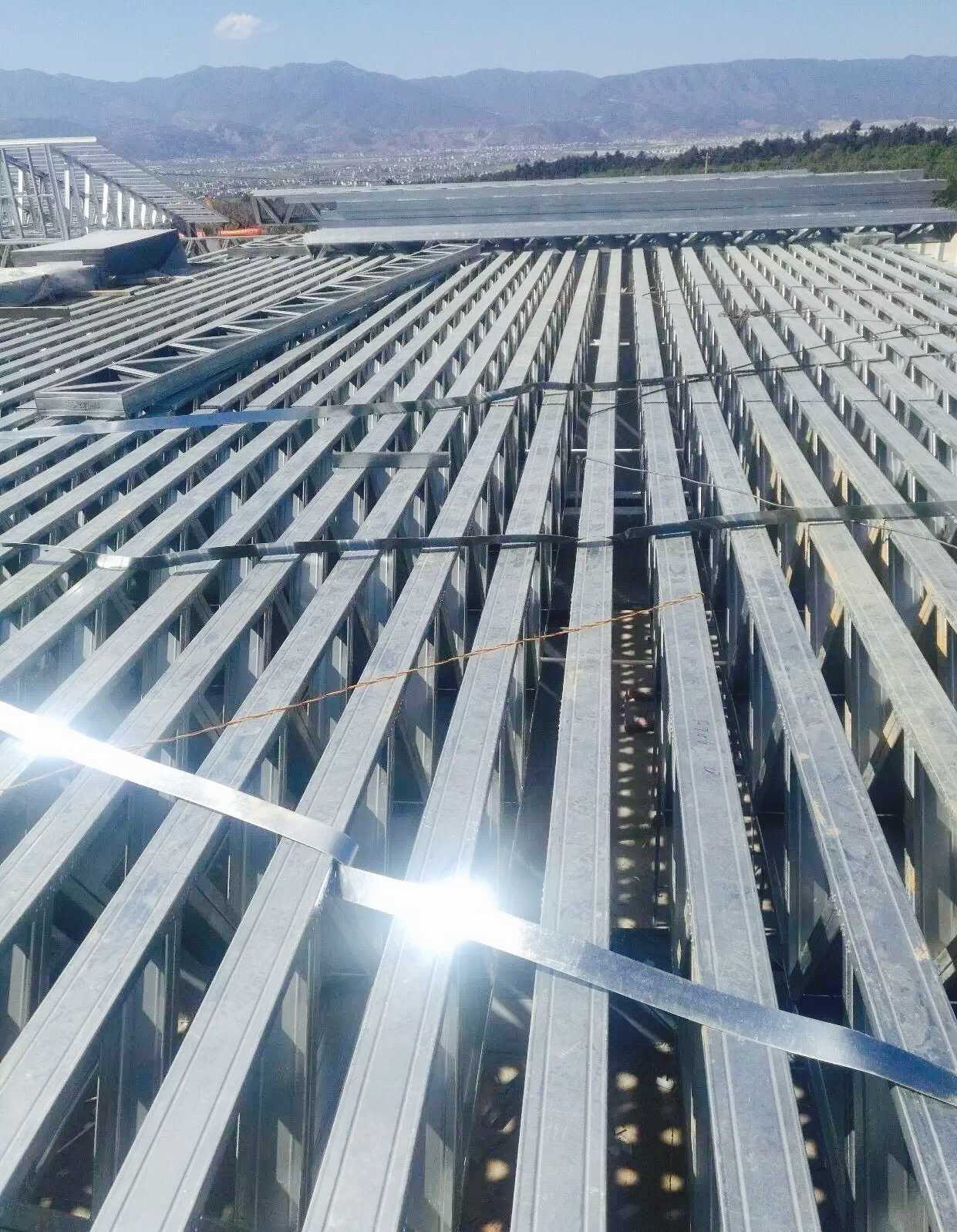

Production Field Required: [15m (frame length) + 7m (machine Line length)] * 2m (width) Machine can be used in a factory or on a construction site. It can even be fixed on a motor vehicle to form a mobile processing plant.

High Production Efficiency

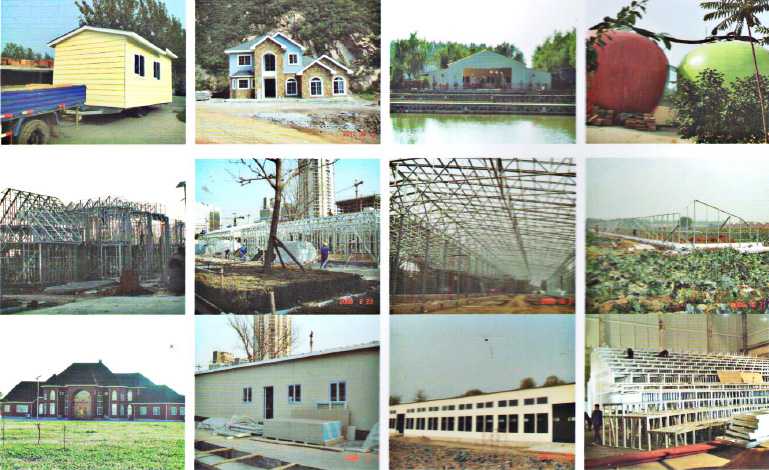

Depending on number of processing node, each machine can process 2000m to 6000m steel frames in a single day (8 hours). This is equivalent to 100 square meters construction area. Housing integration, mass production and industrialisation have become real.

Power

Total power consumption is 5.5KW, three-phase five wires 380V

Structural Features

A. Complied with current national standards, strictly implementing relevant standards.

B. Material strengthening effect on fame surface is calculated and calculation method is provided.

C. Subsequent decoration is fully considered. Extra frames for decoration are not required

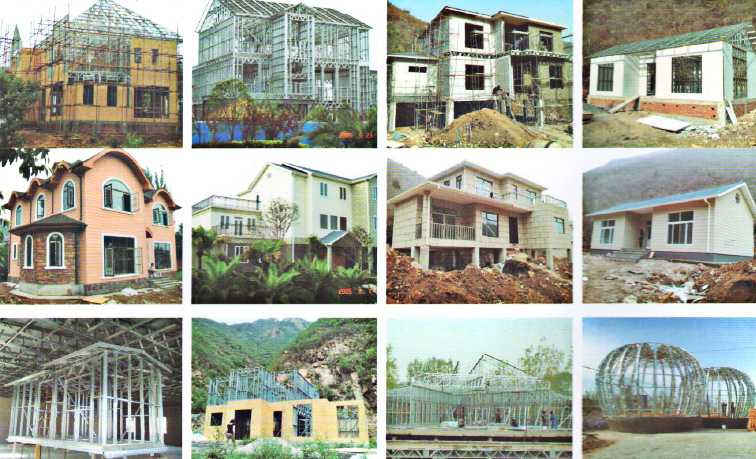

D. Excellent structural mechanics, good force conduction. Large span can be achieved. Floor span is larger than 7.2m and roof truss span is larger than 15m.

E. Steel consumption is as low as 15 to 25 KG per square meter.

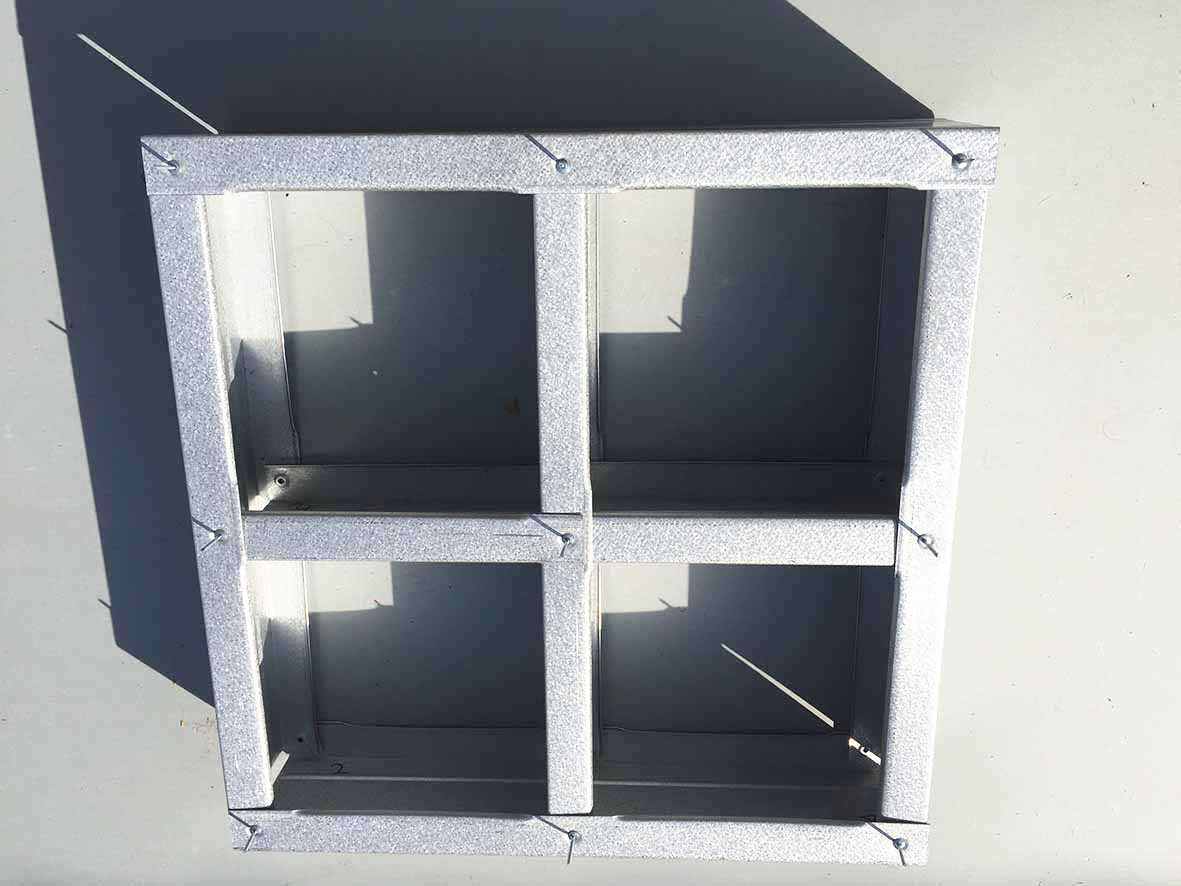

F. One JL-90 machine can manufacture all components including walls, floors, roofs and stairs

G. Less steel varieties are required. Only one type is needed.

H. Stable and reliable. The first roll forming machined was born in 2004. After ten years continuous improvement, failure rate is minimal.

Facades

*Inside - plasterboard to meet water proof and sound proof requirements

*Outside - OSB, insulation board and exterior decoration board

- Insulation board - rockwool board and polystyrene board. Cavity fill insulation should not be used as the only insulation method

- External decoration board - Geil board, metal carved panels, cement class strip board, ecological wood, PVC, reinforced net with cement mortar and so on.

Interior

Plasterboard on each side to meet requirements such as fire safety and sound proof. When calcium silicate board and cement-fiber board are used, an isolated layer should be placed on surface of the keel.

Floor

OSB, calcium silicate board and cement-fiber board. When calcium silicate board and cement-fiber board are sued, an isolated layer should be placed on surface of the keel. Calcium silicate board or cement-fiber board and reinforced net with cement mortar.

Ceiling Insulation

Aluminium foil covered glass wool or glass wool.

Cornice

Calcium silicate board and cement-fiber board.

Roof

OSB

Roof tile

Fiberglass tile, cement tile, Geil tile, metal tile.

Finished product case

Services

A. Each roll forming machine comes with three years warranty.

B. Assisting to provide structure calculation materials for project approval.

C. Sufficient stock of 0.75mm and 1mm thick LQ550 Aluminium and Zinc plated steel.

D. Sufficient stock of special steel rivets, drilling screws and connectors.

E. Loan services are available to customers who have purchased the machine. Frames manufacturing services are also available if customers have insufficient production capacity.

F. Sufficient stock of spare parts. Backup machines are also available during repair.

FAQ

1. I just want to start this business, what should I do?

We will make plans for you according to your budget request and the products range you want to get. If I can be of any help, please be free to contact me, I will provide the best solutions for you.

2. If I don’t know how to operate or encounter technical questions, can I easily get support in spares and technical?

Please make a vedeo of the problems and email to us ,our engineers will be able to work out a video to show you how to settle the problems. In the worst case, our engineers can fly over to help as long as ou can undertake some reasonable charges arouse. For spare parts, it is depends on how heavy to decide to send by air or by sea, for the parts under warranty, we will not charge for you.

Company Information

Our company has the quality management system certification of ISO9001:2008 and GB/T19001-2008.

If you are interested in our Light Steel Keel Roll Forming Machine , please be free to contact me at any time, I am looking forward to getting your email.

Liaoning MEC Group Co., Ltd. is located in China’s famous coastal Dalian city. The company is a comprehensive group, the business scope includes international project contracting, international trade and domestic trade, environmental engineering, e-commerce, real estate and property management, warehousing and logistics , and investment.

The group company was founded in 1994. Up to now, the average annual turnover is around 2.2 billion yuans, of which, the volume of import and export amounts for more than USD 250 millions. The company keeps business relations with several thousand firms and enterprises home and abroad.

All along with the development during the past twenty years, we never forget our responsibilities to the society. The company is persistent in providing supports to the public welfares, its year in year out public donation activities have won broadly recognitions from the social communities as well as governmental authorities.

We adhere, with the company’s good HR resources and scientific management models, the ideas of advance decision making, moderate operation, prudent management, sustainable development, and abide by the core values of being realistic, to create and to share. We do our best to provide our customers with added service.